| Author | Message | ||

| jazzyvee

Senior Member Username: jazzyvee Post Number: 2807 Registered: 6-2002 |

This is painful http://kdbasses.com/forum/index.php/topic,50.msg138.html#msg138 Seems like it was caused by a broken strap on a gig bag.   Jazzyvee | ||

| wishbass

Intermediate Member Username: wishbass Post Number: 172 Registered: 5-2011 |

DOH! | ||

| tbrannon

Senior Member Username: tbrannon Post Number: 1458 Registered: 11-2004 |

Ouch. on a set neck too... I wonder if they could make a cut on the volute and make a scarf joint? It seems like the neck through basses seem to snap at that scarf joint and that the repair isn't too difficult. Not sure how that would work in this case though. | ||

| davehouck

Moderator Username: davehouck Post Number: 10607 Registered: 5-2002 |

Here is a link to the post and to repair pictures. I was thinking the same as Toby; carve away the volute and do a regular scarf joint with a new peghead. But that's not what they did. | ||

| pauldo

Senior Member Username: pauldo Post Number: 795 Registered: 6-2006 |

Subject should have been . . . "Not for the Squeamish" ugh - that is miserable. | ||

| serialnumber12

Senior Member Username: serialnumber12 Post Number: 946 Registered: 12-2004 |

that's why my thick leather strap is screwed into my bass | ||

| dfung60

Senior Member Username: dfung60 Post Number: 544 Registered: 5-2002 |

Youch! Well, on the plus side, you can see the volute did it's job - the extra wood there isn't just a reference point for your fretting hand, it's intended to beef up the critical nut area which would be the thinnest and weakest part of the neck in the event of catastrophe like this. Since the lower part of the headstock survived, it means that this kind of repair preserved all the original wood from the factory in the "business" part of the bass. It looks like the repair that was done tried to preserve the neck and wood, which would have had more impact if a scarf joint were attempted. I wonder if the factory would have done that though - the surface area were the new headstock was added is small and, much worse, it's an end-grain butt joint which wouldn't be very strong. The scarf joint is a lot more work, but the gluing surfaces are along the length of the grain and there's probably 3x the surface, too. The new face laminates should help stabilize everything, but they probably didn't start life expecting they'd be structural members of the new headstock. David Fung | ||

| davehouck

Moderator Username: davehouck Post Number: 10609 Registered: 5-2002 |

David, my guess is that had a scarf joint been done, front and back multi-lams would have been done just as on a regular neck through. Is that what you are saying as well? | ||

| rustyg61

Senior Member Username: rustyg61 Post Number: 467 Registered: 2-2011 |

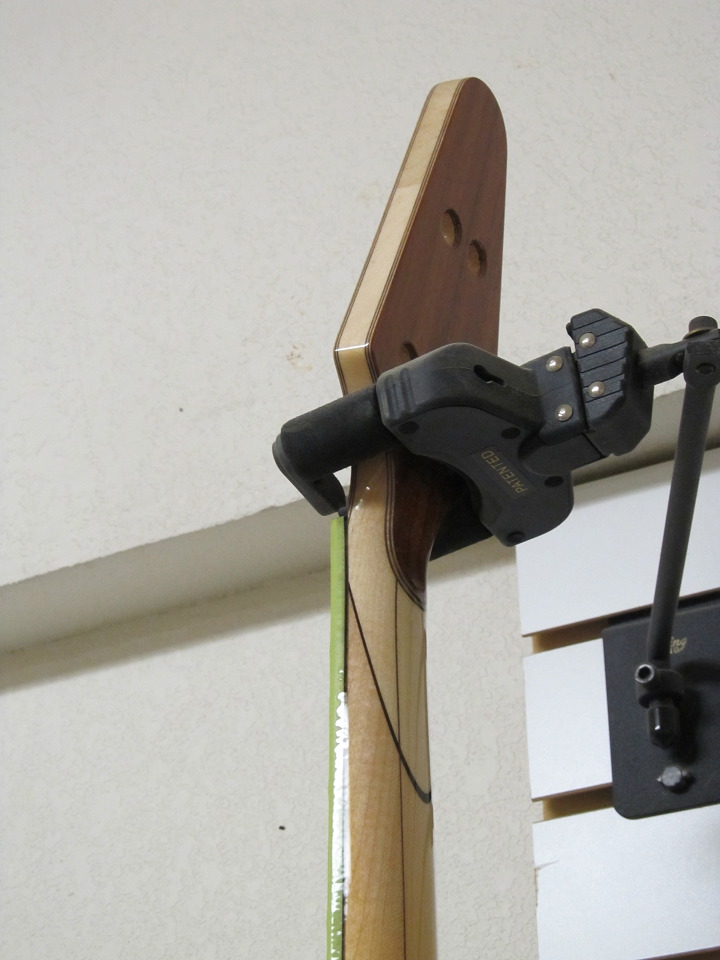

Here's a headstock repair that was at the factory when I toured it last summer. They rebuilt the entire headstock & spliced it onto the neck.  (Message edited by rustyg61 on March 23, 2012) | ||

| pas

Advanced Member Username: pas Post Number: 268 Registered: 3-2003 |

This should serve as a graphic demonstration why a hard shell case is always preferable. I've heard many rationalizations why people use gig bags...but for the life of me, I'll never understand why someone would risk their Alembic. | ||

| nnek

Member Username: nnek Post Number: 72 Registered: 8-2009 |

I agree with David Fung, I think if my neck broke at or relatively near the mounting of the nut (a typical break) a scarf joint at the volute would be in order. But if the break happened much higher up in the peg head, like the 5 string shown above, I would rather retain all the original "meat" of the thru neck design by staying above the volute. | ||

| cozmik_cowboy

Senior Member Username: cozmik_cowboy Post Number: 1183 Registered: 10-2006 |

If I'm not mistaken, Kenn, Alembic only uses volutes on set-neck models (though I do realize what a good chance there is that some one will now post a pic of their neck-through with volute - 'cause there ain't no rules). For the reasons David mentions, I think I would opt for the solution in Rusy's picture. Peter | ||

| dfung60

Senior Member Username: dfung60 Post Number: 547 Registered: 5-2002 |

Dave & others, The scarf joint is harder to execute than the fix here, but the reason it's more desirable is that it presents a larger gluing surface that's distributed rather than concentrated in one line. An endgrain-to-endgrain butt joint is much less strong. In either case, the face laminates are helping distribute the string force across a much larger area, although I think they'll be "working harder" on top of the butt joint. One of the other things that's happening here is that the glue joints are stronger when they are attaching on the long grain rather than end grain. With an Alembic headstock scarf joint, the long grain of the headstock piece is attached to the end grain of the neck piece (I think that's the way it works, anyway). Even that repaired headstock has a thin veneer in the joint, to present long-grain on both sides for the neck pieces to join to. I'm sure the fix on the injured bass would work fine, although I guess it would have been nice to at least have done an angled cut (under the laminations) for the replacement headstock piece. David Fung | ||

| nnek

Member Username: nnek Post Number: 73 Registered: 8-2009 |

Don't get me wrong, I wasn't suggesting a butt end gluing of the head-stock end-grain. If you create a new top of the headstock there is no reason why you couldn't do a scarf joint, as high as, a nice scarf angle allows, up into the tuning machine area of the above illustrated break. After all in Rusty's repair photo above the entire head has been newly re-crafted in order to be scarfed on. Isn't tone and overtone created by string vibration between the nut and bridge, balanced by the sympathy of the wood? I would think that there is some considerable value in trying to preserve the mounting area of the nut, so as to maintain full continuity of sympathetic vibration of the complete neck-through design. It seems a fat volute should be even more valuable to the protection of a through neck design, than to a set or bolt on. When you consider the shorter sympathetic lengths of set and bolt on verses the continuous grain woods, The mid range punch of the set and bolt has a narrower range of harmonics. There has to be some loss through the glue joint no matter how steep the scarf and anything that changes that continuity, potentially changes sympathetic harmonics. |