| Author | Message | ||

| samophlange

New Username: samophlange Post Number: 7 Registered: 5-2009 |

So...I'm looking at pictures of all these beautiful basses, and wondering...how the heck do they make the continuous back plates? Are they cut with a really thin saw blade, or routed out with a teeny weeny router bit? Just amazing. | ||

| davehouck

Moderator Username: davehouck Post Number: 9634 Registered: 5-2002 |

From the Featured Custom layout for Althea, "We make the plates .. with [a] scroll saw to cut the plate before we glue up the body. This reserved piece of wood is then resawn and sanded to form 2-3 veneers. Layered with Maple and Purpleheart, the plate is a little adventure in custom plywood." | ||

| samophlange

New Username: samophlange Post Number: 8 Registered: 5-2009 |

I guess I don't get it. I'm trying to picture how a scroll saw would be able to cut a hole out of the middle of the wood without leaving a cut path to the start of the hole. Like trying to cut a circle out of a piece of paper... Is there a small hole drilled, then the scroll saw fed through the hole? Boy, I need to take some woodworking classes! | ||

| briant

Senior Member Username: briant Post Number: 469 Registered: 12-2004 |

Unless I'm totally misunderstanding how it is done they actually take a thin slice of the same piece of wood and use that to make the plates. So you take one big slice of happy top wood, slice a slab off to use for the actual top of the instrument, then slice off a thinner bit for making continuous plates. Make sense? | ||

| davehouck

Moderator Username: davehouck Post Number: 9636 Registered: 5-2002 |

Robert; I think the way it works is that they draw an outline of the control plate on the board, and then they get the scroll saw and set it up. They then go home for the evening and come back in the morning, and the elves have made the cut. | ||

| edwin

Senior Member Username: edwin Post Number: 734 Registered: 5-2002 |

I think Robert has it right, there must be a small hole drilled and then the shape is cut out, I'm assuming before the piece of wood is glued up. Here's the description of the scroll saw: http://en.wikipedia.org/wiki/Scroll_saw At any rate, I can't wait to see my continuous wood backplates when my S I shows up! I'll be happy to post pictures of the plates, front and back. | ||

| mica

Moderator Username: mica Post Number: 6968 Registered: 6-2000 |

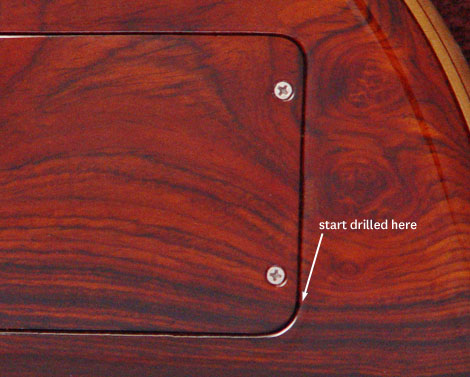

There is a small hole drilled. The scroll saw is fed through the hole. It's a pretty tiny hole, and if you look closely, you can usually spot where the start was. Here's an example from 12-string Leo:  | ||

| mica

Moderator Username: mica Post Number: 6969 Registered: 6-2000 |

I have to admit I can't always find the start hole myself - it is tiny. | ||

| davehouck

Moderator Username: davehouck Post Number: 9637 Registered: 5-2002 |

The process that Brian is talking about is 'nearest neighbor', which has been used in some applications. | ||

| mario_farufyno

Senior Member Username: mario_farufyno Post Number: 543 Registered: 9-2008 |

Wow, Mica, Alembic's craftsmanship is astounding! | ||

| samophlange

New Username: samophlange Post Number: 9 Registered: 5-2009 |

That's some awesome work. It creates quite the stunning result! Thanks for the info. It definitely took the "how the @#$%?" look off my face. | ||

| rjmsteel

Intermediate Member Username: rjmsteel Post Number: 112 Registered: 7-2008 |

Thanks Mica for that tutelage on the C. Backplates process. Can`t wait to see how the Colo bolo plates look on my Series bass when, (in due time), the bass arrives! | ||

| edwin

Senior Member Username: edwin Post Number: 753 Registered: 5-2002 |

OK, I've got my continuous wood back plates in hand and they are stunning as I expected. The control covers seem pretty obvious how they were cut out, but the part that I still can't figure out is the battery compartment. Is there a saw that has a right angle in it? | ||

| sonicus

Senior Member Username: sonicus Post Number: 1328 Registered: 5-2009 |

Like a router with a template ? | ||

| edwin

Senior Member Username: edwin Post Number: 757 Registered: 5-2002 |

Routers do that? How does a router reserve the plate? My battery compartment cover is from the neck wood. How do they cut that out and leave a shelf below when the rest of the piece of wood is solid through to the top? I'm thinking maybe the neck is made a little deeper and then a slice is cut off and the cover made from that. Next, the battery hole is routed as it would be if it had a brass cover. | ||

| cozmik_cowboy

Senior Member Username: cozmik_cowboy Post Number: 791 Registered: 10-2006 |

I believe I recall reading that neck-wood covers, like non-laminate back covers, are done with a nearest-neighbor slice. Peter | ||

| mica

Moderator Username: mica Post Number: 6995 Registered: 6-2000 |

Righto, Peter! The continuous wood plates for truss rod covers on instruments without bookmatch to center and neck-mounted backplates are in fact the very next slice of wood. |