| Author | Message | ||

| jazzyvee

Senior Member Username: jazzyvee Post Number: 4667 Registered: 6-2002 |

Just got my series II bass out for a practice session at home in prep for my gig on Saturday and decided to use the jack socket instead of setting up the DS-5 and 5pin cable. Lo and behold the jack won't stay in the socket. it's moved inside and little and the jack won't fully engage in the socket so keeps pushing out. I took off the cavity cover and it's all hidden behind the pots and looks a fiddly job to get something in there to tighten it up whatever fixings there are. I have to say it's something i was concerned about for both sockets but the jack has never felt solid and I have used the jack socket less times than I can count on both hands. However the 5pin seems made from a huge gold plated piece of metal that doesn't look like it's moving anywhere although it is always difficult to remove the 5 pin socket so I do have a little concern here. Anyway I won't be able to look at it until after my gig but any tips to get it fixed would be welcome. It's edge mounted somehow from the inside and hidden in that recess behind that dual pot. I expect to have to remove a lot of stuff to get at it. http://www3.alembic.com/img/13094_monooutput.jpg   | ||

| dfung60

Senior Member Username: dfung60 Post Number: 616 Registered: 5-2002 |

This kind of edge-mounted jack is usually a "deep-panel" jack. There's no mounting hardware on the outside of the instrument. Usually, the length of the jack body is threaded, and there's a locknut that threads on from the back side. A common one is the Switchcraft 151 (google it). Your bass doesn't have this Switchcraft part because a Series bass has stereo output and would require an extra set of contacts to control the power. But it probably attaches the same way. Now, the really bad news. Not only would you need to remove the dual pot but you have to hope there's enough slack in the wiring to give you access to the locknut. If not, then you may have to remove more of the electronics harness to get access. And depending on how far in the body the locknut is recessed, you may need to remove the leads from the switch to get in there with a deep socket. This is one of those examples where they start building your bass with the output jack, then build the entire bass around it! Hopefully, the mothership will have additional instructions. David Fung (Message edited by dfung60 on September 16, 2015) | ||

| jazzyvee

Senior Member Username: jazzyvee Post Number: 4680 Registered: 6-2002 |

Hi David, I was hoping that was not gonna be the situation that I have to remove any connections. However I think you are correct. the screw(s) holding the jack to the body seems to have stripped the wood since it moves back and forth when a jack lead is inserted. I had a chat with Mica on the phone earlier this week and sent her some photo's and she replied last night with some guidance on how fix the hole. Apparently mine is one of only a few to have that particular jack and fixing so others like Rusty with newer side mounted jacks should not have this happen. Anyway I might be brave enough to strip it down at the weekend and hope it's an easy fix and I don't render the bass to ornamental piece of wood and metal as a result. It's not a major problem because I always use the 5pin setup but having the jack as a backup is a good bit of security. | ||

| dfung60

Senior Member Username: dfung60 Post Number: 618 Registered: 5-2002 |

I just looked at the photo again. Is the jack secured by the black phillips head screw in the upper left quadrant? If that's a wood screw that's holding the jack in and the threads are stripped, then you can try to take the screw out (may require an offset screwdriver), dip a toothpick in white glue, then jam it into the screw hole. Let it dry and put the screw back. That might do the trick. I don't think Switchcraft makes a deep panel jack that has stereo+power switch. In that design, the entire jack body is threaded and it would be quite hard to get to the nut that secures the jack if it's recessed in the body cavity. A modification of this Switchcraft jack was quite popular on acoustic guitars as an endpin jack. Since there's a block of wood inside the body there, it's a good location for strength, but putting the nut on the inside of the guitar body is quite diabolical. David Fung | ||

| jazzyvee

Senior Member Username: jazzyvee Post Number: 4681 Registered: 6-2002 |

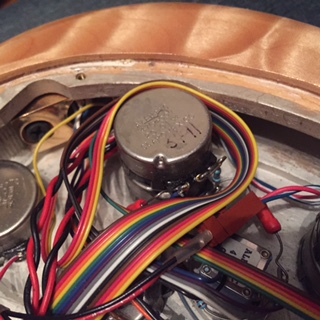

The jack seems to be secured by a single black screw. If I put a jack plug in I can clearly see that the whole assembly is loose and the screw is not gripping the wood. The above picture isn't very clear so I've included another with this post. I guess everyone learns lessons when things like this happen and I'm sure this particular one alembic learned way back as they do it in a different manner now. But it is what it is and I need to fix it. :-)  | ||

| ed_zeppelin

Member Username: ed_zeppelin Post Number: 95 Registered: 2-2010 |

You can stick the eraser end of a pencil into the jack and use the friction of the rubber to pull the jack out. This tip might not work in this case, but it will come in handy for barrel-type jacks or some of the weird injuries gravity inflicts upon side-mounted jacks (Ibanez, Fender and Hagstrom seem to specialize in bizarre experiments with cup-type ferrules coutersunk into the body, with no way to access the jack from the inside.) Believe me, there was a whole generation of kids who didn't use straplocks, and when their Kramers suddenly fell straight down it would just BURY the jack somewhere up in there. Fun. You can also use a dental pick, but the pencil makes a dandy guide to make the tip of the Jack line up with the opening as you pull it out.. I made a refinement that really makes the eraser grab. It comes from Earl Scruggs' method for keeping his thumbpick on. Earl inserted a sharp knife tip into his thumbpick (from the top) at a shallow angle to create barb-like grooves on the "thumbprint" surface that gripped the pad of his thumb. I do the same thing to the pencil eraser. Use a razor or exacto knife to create lots of tiny nicks all over it, each at a sharp angle toward the pencil point. When you pull the eraser toward you, the "barbs" in the rubber grab the inside of the Jack. I've done it thousands of times. I hope that helps. | ||

| mica

Moderator Username: mica Post Number: 8631 Registered: 6-2000 |

Those few sculpted brass mountings had a shared screw between the 5-pin and the 1/4" jack which are separate little sculptures. I suppose this could be the only one with one screw, but do check that carefully or else you might do damage when trying to remove it. David's advice is exactly the same I gave you by email as far as repair goes, so there's a little glue in your future I'm afraid. The jack is a Switchcraft, and this bass was made at a time before we convinced them to make long frame jacks as a custom order item for us. For decades they tell us they don't make a certain connector, and after we speak an engineer, they remind the sales department that they do make the part we need. The problem with the long frame jack is revealed in its name: it' l-o-n-g. You can't retrofit in this case, and you can't retrofit for a barrel jack either. If you order a new Series I or II with side jacks, we'll use one of these long-frame jacks provided there isn't lots of extra custom electronics, in which case we recommend a side-mounted 5-pin and a face-mounted 1/4" jack, which gives the most space in the cavity. | ||

| jazzyvee

Senior Member Username: jazzyvee Post Number: 4684 Registered: 6-2002 |

Can I take it that all those connectors on both sockets are soldered on so moving things about isn't going to pull a connector of one of the lugs. :-) I'd hate to have to get my fingers in there to push anything back. | ||

| mica

Moderator Username: mica Post Number: 8633 Registered: 6-2000 |

Yes - the wires to both connectors are soldered, protected under shrink tubing. If you first remove the filter pot (and the adjoining Q switch) obstructing the path, you should be able to get in there to do work with little incident provided you use a little care and take your time. Also, take pictures every step of the way for notes. | ||

| rustyg61

Senior Member Username: rustyg61 Post Number: 1746 Registered: 2-2011 |

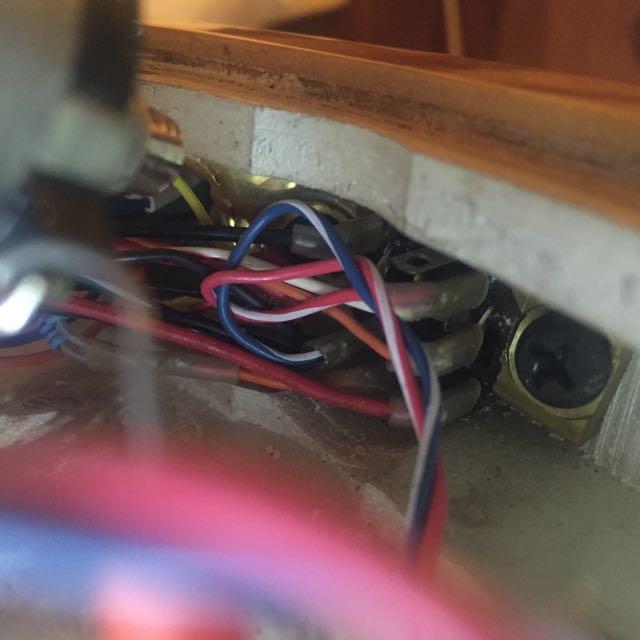

Hey Delano, not sure if this will help, but here's a picture of the jack Mica used for a mock up when we laid out where I wanted my controls.  | ||

| jazzyvee

Senior Member Username: jazzyvee Post Number: 4725 Registered: 6-2002 |

Your jack is different to mine and mine sits on the lower bout of the bass close to the bridge filter control so probably more tricky to get to. I haven't found free time to get it dealt with yet. Probably have to wait till I have a free weekend. |