| Author | Message | ||

| kungfusheriff

Senior Member Username: kungfusheriff Post Number: 598 Registered: 8-2003 |

The bad news is Lil' Black and Tan (82 2327) is sick from a broken wire and is humming like a swarm of bees. The good news is my band plays so damned loud it's inaudible onstage. ;) During soundcheck last night I was getting some serious hum from the neck pickup that wasn't alleviated no matter how I adjusted the humcanceller trimpot, and no hum at all from the bridge pickup. Opening up the control cavity, I found that (if I'm figuring this correctly) the connector that attaches the neck pickup lead to the circuit board mounted on the control cover cavity was the culprit. One of the wires, which I assume is the lead from the neck pickup, is intact while the second, which I assume connects the neck pickup to the humcanceller circuit, is broken clean off just after it disappears into the port in the connector. I can post a pic should this be necessary for the diagnosis. Unless I'm completely wrong, fixing the break should be no big deal -- after extracting the wires from the connector, I figure I'll have to trim the intact wire to the appropriate length, strip some of the insulation from both leads, and re-insert the bare ends back into the connector. Am I seeing this correctly? Any advice? | ||

| davehouck

Moderator Username: davehouck Post Number: 4999 Registered: 5-2002 |

A picture might be helpful. | ||

| dfung60

Advanced Member Username: dfung60 Post Number: 246 Registered: 5-2002 |

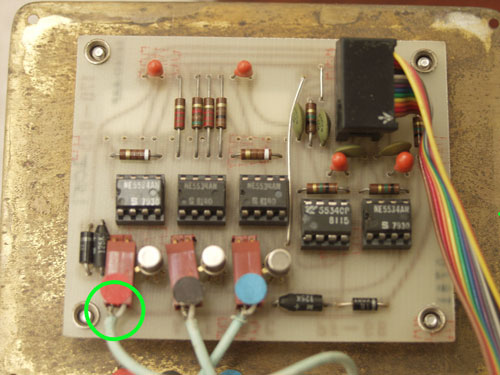

Does your EQ board look like this (well, hopefully less blurry)? <img> If you've identified the problem as a break in the connector in the green circle, then you've probably found the problem, but it won't be quite as easy to fix as you hoped. This is a 2-pin Molex connector. The two leads coming into the connector are the signal and ground lines from each coil. As is evident on mine and probably similar on yours, one of the leads is a regular wire, the other is the braided shield from the pickup. The way that a Molex connector works is that a small j-shaped metal lug is crimped onto the end of each wire with a special tool. Then, the lug is pushed into the brown connector body. The tail of the "J" is actually a latch that grabs onto a ledge inside the brown connector and probably isn't going to let go without a pretty good fight. If you have a very fine pointed probe (like a dental probe), you can push in the open hole on the side of the connector and you might be able to dislodge the latch and push the wire out. But often when you try to do this, you'll actually bend the lug and then you'll find that you can't get it back into the connector after you've reattached the wire, or the connector won't make solid contact with the square peg that it pushes on to anymore. You have two alternatives. The easy fix is to cut the Molex connector off and solder the two contacts directly to the molex pins. You'll need to shrink wrap the connections if you do this. You won't be able to unplug the board without cutting or desoldering, but you probably weren't going to do that anyway. The harder fix would probably be to cut the Molex connector off, remove the pickup entirely from the bass (I doubt that the Molex will fit though the wire route in the body), and send it back to Alembic. They can put two new lugs on leads and send you a new Molex body. You then feed the leads and lugs back through the body, insert them into the connector body until they latch (doens't require tools, but you do have to position them correctly before you push them in) and plug the new connector into the EQ board. You could probably try to install the lugs yourself, but the problem is that the lug is shaped to hold the wire, latch into the body, and provide spring pressure against the post. If you deform the lug at all, it probably won't work reliably. The leads don't attach by being stuck into the connector. Hope this helps, David Fung | ||

| dfung60

Advanced Member Username: dfung60 Post Number: 247 Registered: 5-2002 |

Whoops, the board doesn't like image references outside the alembic.com site. Here's the picture! (This is from my 1983 Series Exploiter)  | ||

| kungfusheriff

Senior Member Username: kungfusheriff Post Number: 599 Registered: 8-2003 |

David! My savior! Yep, that sounds about right, and I'll likely go with option A...thank you! | ||

| davehouck

Moderator Username: davehouck Post Number: 5001 Registered: 5-2002 |

Let us know how you make out. | ||

| terryc

Intermediate Member Username: terryc Post Number: 172 Registered: 11-2004 |

If it is of any informational use, the same fault occurred with my P/J pick ups on my old Squier,one wire had broke on the split PU.As David said, cut the wire and solder directly to the pins, makes the idea of solderless joints redundant but gets you back in business | ||

| kungfusheriff

Senior Member Username: kungfusheriff Post Number: 616 Registered: 8-2003 |

OK, I finally got around to fixing this -- what I did was, rather than hard-wire the leads to the circuit board, I used an awl to widen the aperture of the contacts inside the clip-on connector, jammed the wires into the contacts, and painted a thin coat of superglue over the whole thing. I played the bass for a bit last night and all seems to be well. God, what an instrument. | ||

| davehouck

Moderator Username: davehouck Post Number: 5399 Registered: 5-2002 |

Cool! | ||

| dfung60

Advanced Member Username: dfung60 Post Number: 265 Registered: 5-2002 |

KFS - hmmm... I'm glad that your bass is alive again, but I don't know whether you'll have good dependability from your fix, as you've described it. The molex connector has a bunch of parts in it that are designed to be relatively cheap but fit together in a fairly precise way. The conductor (crimped on the ends of the wires but hidden inside the brown plastic connector body) is very precisely shaped to put just the right amount of pressure on the square post that the connection is physically strong and soemwhat airtight at the point of contact. The theory here is that the tight tolerance fit will prevent corrosion on the square pin (the connector here is probably not gold plated, but those are available as well for really critical applications). If the connection is compromised by corrosion, then sliding the connector on and off a couple of times will wipe the corrosion off. If you bend the contact, you might get better contact now, but might not be better in the future, plus you'll lose the self-cleaning of the connector. On top of that superglue can be pretty fragile. I'd reconsider soldering the connection directly. If you don't want to lose a pickup to Alembic for repair, you might try writing to see if they can send you the molex pins and connector body. They are normally crimped on, but you can solder the contacts if you're careful (the soldered connection still has to fit in the connector body). The contacts have a kind of "J" shape, so they can only be inserted into the body once before the latch into place. Good luck, David Fung | ||

| davehouck

Moderator Username: davehouck Post Number: 5408 Registered: 5-2002 |

Pictures of what David is describing are here. | ||

| kungfusheriff

Senior Member Username: kungfusheriff Post Number: 617 Registered: 8-2003 |

Cool! Thanks for the link, Dave, and Mica for the tutorial. David, I'm not seeing this as a permanent fix, but considering present constraints on my time and money I'm happy with this solution for the time being. As always, I'm glad to benefit from your experience. Again, thanks, all. | ||

| terryc

Advanced Member Username: terryc Post Number: 234 Registered: 11-2004 |

davehouck & dfung60 - my 'quickfix'on my old squier..could I reverse it back to the clips, would I need a special crimp tool for the wires, I have a standard crimper which does the same thing. Mind you it has been soldered for years and has stood up to the the huge rigours of my son in his emo/rock band. | ||

| dfung60

Advanced Member Username: dfung60 Post Number: 267 Registered: 5-2002 |

The contact pieces for these Molex connectors are *really* small (if you look at the photo link that moderator Dave posted, you can see the size). The square pins are only 0.10" apart. A standard crimper which punches in to the back of the contact (the punch isn't shown in this picture) would be way too big. I guess you could close the crimp connector on the wire with delicate application of needlenose pliers, but if you deform the flat part of the contact in the slightest, then you won't get dependable contact. If it were up to me, I'd stick with the soldered connection which will be more reliable, electrically more sound, and easily reversible. David Fung | ||

| terryc

Advanced Member Username: terryc Post Number: 235 Registered: 11-2004 |

David - thanks for advice and it has been like that for a long time so if it ain't broke(yet) don't fix it | ||

| georgie_boy

Advanced Member Username: georgie_boy Post Number: 284 Registered: 8-2005 |

Can we all agree gentlemen, that David Fung is a master !! | ||

| georgie_boy

Advanced Member Username: georgie_boy Post Number: 285 Registered: 8-2005 |

Ooooops! Not forgettng Kimberley and all the other ladies. Accept my apologies-please G |