| Author | Message | ||

| rustyg61

Junior Username: rustyg61 Post Number: 41 Registered: 2-2011 |

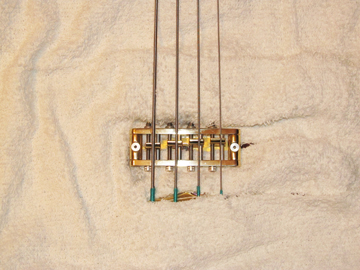

This may have already been covered, but here's an idea I had to protect my bass while polishing the bridge. I took a towel & cut 2 slits in it to go under the bridge & tailpiece, then slid it under the strings & bridge & around the tailpiece. This protects the wood from the black residue from the polish. You can use the same towel around the nut too. I used the Eagle One Never Dull wadding polish that Joey suggested, & it works great! In about 5 seconds the tarnish is gone & the shine is back! Then I sealed it with VO5 in the gold tube (also Joey's suggestion). Here are some pictures -    | ||

| billostech

Intermediate Member Username: billostech Post Number: 111 Registered: 1-2011 |

Great suggestion Rusty. I followed your instructions and both of my basses have shiny bridges, nuts, and tail pieces. The Eagle One Never Dull works great. Thanks Joey!!! I have not tried the VO5 yet. Where is Joey's post on it. | ||

| jcdlc72

Member Username: jcdlc72 Post Number: 68 Registered: 11-2009 |

I have a question, though. In the almost two years I've spent with my beloved Epic 5, I have never polished the bridge/nut/tailpiece. It seems like I should, since they are looking a little bit dull already. I am, however, VERY afraid of wearing out the wood by unscrewing/screwing the tailpiece. I have a suspicion it might be screwed with machine screws on inserts (just as the control cavity and truss rods cover plates are), but am not sure, and certainly am not willing to do the test. Can anyone tell me whether those are directly screwed on the wood, or with inserts? In any case, are there any other experiences (besides this one, which I consider a wonderful option) on polishing bridge and tailpiece, which result in an unharmed body finished? Thank you very much in advance! | ||

| rustyg61

Junior Username: rustyg61 Post Number: 42 Registered: 2-2011 |

Here's Joey's post on using VO5 to prolong the shine on brass - http://alembic.com/club/messages/393/2448.html?1038492414 | ||

| billostech

Intermediate Member Username: billostech Post Number: 112 Registered: 1-2011 |

Thanks Rusty. | ||

| rustyg61

Junior Username: rustyg61 Post Number: 43 Registered: 2-2011 |

You're welcome! | ||

| billostech

Intermediate Member Username: billostech Post Number: 113 Registered: 1-2011 |

Juan, I should have took some decent before pics, but here are the after:   | ||

| tbrannon

Senior Member Username: tbrannon Post Number: 1300 Registered: 11-2004 |

Cool little trick! I would still recommend taking the whole bridge off and apart at some point for cleaning. It really helped me understand the design of the instrument, which then made it easier for me to tackle setups, etc. Plus, you take the bridge apart and start looking at the super simple, yet elegant design and it makes you appreciate the folks at Alembic even more than you already do. | ||

| rustyg61

Junior Username: rustyg61 Post Number: 44 Registered: 2-2011 |

Looks great Bill! I'm sure at some point I will totally disassemble my bridge to do a thourough cleaning, but the towel works for the post-gig cleaning I do after each performance. I would suggest that if you do remove your bridge for cleaning, first tighten the adjustment screws until they bottom out on the baseplate, & count the number of turns on the screws. Then when you put it back on the bass, you can set it back to the same height it was before & keep your same action. Someone suggested taking a picture of your bridge before you disassemble it too so you can see the orientation & position of the saddles for reassembly. You will still probably have to do some minor tweeking to set your action & intonation, but at least you will be in the ballpark. | ||

| bigredbass

Senior Member Username: bigredbass Post Number: 1635 Registered: 9-2002 |

Juan Carlos, I believe if you follow the bridge height screws into the body, you should be able to see them going into metal inserts in the body. I can't say for sure if this is standard construction spec across all Alembic instruments (Mica . . . . . ?), but I would be surprised IF yours is screwing directly into the top of the body. Remember we're talking about polishing ONLY the unfinished parts here . . . so do NOT try and use a brass polish on clear-finish or plated parts (anything with a chrome or gold-plate or black finish). So generally we're talking about the bridge and adjustable nut on most, but not all, Alembics. If all of your hardware is gold or chrome or black plated, do NOT do this, as it can scuff the plated bits just like sandpapaer. Also, on most Alembics, the tailpiece and the brass back cover plates are clear plated, so we don't want to brass polish these either. Generally on plated parts (both of mine have gold tuning keys), a little automotive wax works well, JUST a little. And be sure you use wax, NOT wax-polish. In auto refinishing circles, wax is only wax: A polishing wax usually includes a bit of polishing compound, which again, can tend to act like fine sandpaper on finished parts, so be sure which one you're about to use. BTW, a good wax is also a great guitar polish if you have clear gloss finish on your basses like me. I'm a huge Barry Meguiar fan (I'm Car Crazy!) so you can guess I'm not using Mother's . . . . Again, be sure it's wax and not polish. The Eagle One Nev'r Dull is FAST on brass, but can leave quite a bit of black residue, so be sure you get it all off with a clean, dry rag. I also put rags under mine if I do it on the bass, can not get a good answer from Eagle One that it's as inert as the other things in my cleanup bucket, so Rusty has the right idea. J o e y | ||

| bigredbass

Senior Member Username: bigredbass Post Number: 1636 Registered: 9-2002 |

Bill, I ran across the VO5 tip in a 'Hints from Heloise' ( . . . yeah, I can't believe a full-growed man was reading that stuff, either !) about keeping sterling silver houseware shiny after it's polished. It's completely organic, harmless to finishes and electronics, and provides some protective film to the newly-polished metal. Cheap, works great. A little dab'll do ya ! You'll be pleasantly surprised just how long the shiny bits will stay shiny after you do this. J o e y | ||

| billostech

Intermediate Member Username: billostech Post Number: 115 Registered: 1-2011 |

Thanks again Joey. I plan on removing the bridges and giving them a good cleaning this weekend as Rusty suggested. I will appy the VO5 at that time. | ||

| rustyg61

Junior Username: rustyg61 Post Number: 47 Registered: 2-2011 |

Thanks for clarifying that Joey! I failed to mention that I did not use the Nevr-Dull on my tailpiece because it is clearcoated. What do you use to apply the VO5? I just put a small amount on an old T shirt & rubbed it into the shirt, then rubbed down the brass. I noticed that I still got a small amount of black residue when applying the VO5 even though I cleaned the brass thoroughly after using the Nevr-Dull, so it acts like a cleaner & sealer. | ||

| mario_farufyno

Senior Member Username: mario_farufyno Post Number: 610 Registered: 9-2008 |

Is this you are talking about? http://www.vo5haircare.com/products/#conditioning-treatments/original Really? | ||

| cozmik_cowboy

Senior Member Username: cozmik_cowboy Post Number: 909 Registered: 10-2006 |

Great info, Joey - but as a former (way former) VO5 user (hair, not brass), I feel obligated to point out that "a little dab'll do ya" was Brill Cream.  Peter | ||

| bigredbass

Senior Member Username: bigredbass Post Number: 1641 Registered: 9-2002 |

Yeah, I know, Pete: Just fishing to see who else was as old as me ! Yes, Mario, that's it. Geez, EVERYTHING has a website. Just think of it as the way you'd leave a fine film of oil on a firearm after it's been cleaned, same idea. You can leave this on plated parts as well, but as discussed above, you don't want to use anything abrasive on plated and/or clear-coated parts. J o e y | ||

| pierreyves

Senior Member Username: pierreyves Post Number: 783 Registered: 11-2006 |

Hi, personnaly I removed all hardware part of one of my SC deluxe, go with to the plater for gold plated (about 300 USD in Switzerland) and never remove after that. I move a little my tailpiece because not centered and no problem: you do 3 small holes adapted to screw with machine and the old ones, you put some wood and glue. | ||

| bigredbass

Senior Member Username: bigredbass Post Number: 1643 Registered: 9-2002 |

HERE's Eagle One's web page for Never Dull: http://www.eagleone.com/pages/products/product.asp?itemid=1006&cat=5006 I also have an inquiry posted to them tonight regarding how safe it is for wood finishes, so I'll report back what they reply when they get back to me. J o e y | ||

| billostech

Intermediate Member Username: billostech Post Number: 117 Registered: 1-2011 |

Thanks again Joey!!! | ||

| mario_farufyno

Senior Member Username: mario_farufyno Post Number: 611 Registered: 9-2008 |

Thanks, Joey (amazing, I would never think using this) | ||

| bigredbass

Senior Member Username: bigredbass Post Number: 1644 Registered: 9-2002 |

OK, so I have a reply from the guys at Eagle One, quote: "Thank you for your question. The Nevr Dull product is a very unique product with the wadding material that contains a special polishing substance that is solely recommended for metals, such as brass, copper, aluminum, etc.. Paint finishes in general, (clearcoat, polyurethane, lacquer, etc.) is something that we do not recommend this product for, simply due to the abrasiveness of the product. The wadding material in the Nevr Dull still contains a lot of the original cotton seeds, therefore we see this being a potential risk of scratching the painted surface if used. We do apologize for the inconvenience, however we cannot stand behind the use of this product for that purpose." So, essentially, how I (and Rusty) have been using this stuff is correct: Keep it OFF the painted surfaces, keep it to the unfinished brass ONLY. This is the first time I've gotten a solid answer about this stuff, and I did imagine it was NOT good for painted/plated surfaces. And of course, IF this puts you off using it, that's up to you. I'm certain ALEMBIC doesn't need any finish problems caused by ham-fisted users, nor do they honor any 'self-inflicted' finish problems, and they should not have to fix something that's all my fault. But it is very fast and I'm very careful with it, so do what is best for YOU. I'm very big on using things that are as inert as possible (I need all the help I can get NOT messing things up), so I can now imagine I'm now looking for a new (harmless) brass polish ! BTW, for the life of me, I can NOT find ANY lemon oil that's petroleum free, even at Whole Foods or Trader Joe's (yes, we have tree-hugging grocery stores in Nashville now !). Anybody tip me off to where I can find any? J o e y | ||

| sonicus

Senior Member Username: sonicus Post Number: 1720 Registered: 5-2009 |

Hello Joey , I have been using this; http://www.auracacia.com/auracacia/aclearn/eo_lemon.html Reading the label on the bottle it reads 100% pure essential oil . Ingredients ; Citrus X limon (lemon oil) . No mention of petroleum base. I picked it up @ Whole Foods In Berkeley, CA. Wolf AKA Sonicus | ||

| sonicus

Senior Member Username: sonicus Post Number: 1721 Registered: 5-2009 |

Hello . it's me again Joey. There you have it ; http://www.vitacost.com/Aura-Cacia-100-Pure-Essential-Oil-Lemon Wolf | ||

| edwin

Senior Member Username: edwin Post Number: 887 Registered: 5-2002 |

Or if anyone can't find it and needs another option, my wife, Dawn, has offered up an Alembic discount for her aromatherapy grade lemon essential oil. Back when we lived in Boston, she made a special blend for upright bassist Larry Roland for his ebony fingerboard. It was the best smelling bass in Boston! www.artscent.com or call her at 800 551 0701. Afternoons are best and her assistants may not know what the heck you are talking about. | ||

| rustyg61

Member Username: rustyg61 Post Number: 51 Registered: 2-2011 |

Thanks Joey! Now I'll be even more cautious making sure the towel completely covers the wood while using the Nevr Dull. I just like the way it is impregnated into the cotton, it is less messy than using a cream polish on a rag. I only tear off a piece about the size of a pick, so there is no excess flopping around hitting parts it shouldn't! I also use Alembic's Supreme Polish - http://www.alembic.com/prod/polish.html - after using the Never Dull in case I got any residue on the wood. The polish will clean the wood of any solvent before it has a chance to harm the finish. | ||

| rustyg61

Member Username: rustyg61 Post Number: 52 Registered: 2-2011 |

Thanks Wolf & Edwin! Does Lemon oil keep for a long time, or should I buy it fresh when I'm ready to use it? My bass is only a month old, so hopefully I won't need it anytime soon. | ||

| rustyg61

Member Username: rustyg61 Post Number: 53 Registered: 2-2011 |

Hey...I just noticed that I graduated from "Junior" to "Member" on the forum! I guess after 100 posts I'll be an "Intermediate Member." How many posts do you have to have to be a "Senior Member?" | ||

| elwoodblue

Senior Member Username: elwoodblue Post Number: 1214 Registered: 6-2002 |

I think just 200...congrats ; )) | ||

| lbpesq

Senior Member Username: lbpesq Post Number: 4794 Registered: 7-2004 |

Anyone have an opinion as to how "Nevr Dull" compares to "Flitz"? Bill, tgo | ||

| sonicus

Senior Member Username: sonicus Post Number: 1722 Registered: 5-2009 |

I personally prefer "Flitz" for all my metal polishing applications . Why? Flitz is non-abrasive. I use it on my brass Alembic parts and I polish my vintage Silver plated Bach and Selmer Paris raw brass trumpets as per recommendation of my trumpet tech . Flitz will not scratch your metal .I have used "Never Dull" on other items such as wheel spokes or oxidized / rust spots on vehicles, etc... | ||

| dfung60

Senior Member Username: dfung60 Post Number: 486 Registered: 5-2002 |

Kind of interesting about Flitz. When I saw sonicus' post saying Flitz was non-abrasive, I thought must have been a mis-read. Polishes have to be abrasive to work (they scratch off the oxidized surface of the metal). Googled it a bit, and it's interesting that the company that makes Flitz claims that it's non-abrasive, but if you look at the safety sheet for Flitz paste (required for chemicals), the primary agent is aluminum oxide which is an abrasive. Strange that they would market it as non-abrasive, because it's just not true. The differences in polishes is how fine the abrasive particles are. Rougher particles can cut through oxidation quicker but leave visible scratches. Fine cuts wouldn't be able to polish out deep scratches but leave a mirror-like finish. So, I'm sure Flitz is suffering from some hyperbole here - they have a fine cut of alumina so you don't see scratches. You could have a purely chemical polish, but it's unlikely you'd have a mirror-like finish on metal after using it. David Fung | ||

| sonicus

Senior Member Username: sonicus Post Number: 1732 Registered: 5-2009 |

HI David , yes as per the MSDS you are correct , yet in practicle application I personally have found Flitz to be the least damaging of the products that I have used on brass & silver surfaces. Perhaps it has the least abrasive effect as per the manufactures claims. here is the MSDS that David pointed out for us; Thanks for the research David. Wolf http://www.flitz.com/images/document/MSDS_Flitz%20Polish_PASTE.pdf | ||

| sonicus

Senior Member Username: sonicus Post Number: 1734 Registered: 5-2009 |

Fliz's claims indeed are interesting ; http://www.flitz.com/t-faq.aspx Wolf | ||

| lbpesq

Senior Member Username: lbpesq Post Number: 4799 Registered: 7-2004 |

And it's a dessert topping too!!! hehehehe Bill, tgo | ||

| sonicus

Senior Member Username: sonicus Post Number: 1735 Registered: 5-2009 |

I am now intrigued to get a first hand explanation form Flitz @ their 1-800-558-8611 number regarding the MSDS and their claims on their product description regarding being "non abrasive". I will report back , feel free to call as well . Wolf, Sonic Regards _______ | ||

| sonicus

Senior Member Username: sonicus Post Number: 1737 Registered: 5-2009 |

I just spoke with a representative from Flitz regarding the " non abrasive product description " and the MSDS . I was told that as per the The U.S. Government ; Flitz is considered a non- abrasive polish. As per the Canadian Government even water can be considered abrasive. The Aluminum Oxide is 5000-6000 grit . I was told that if anyone has any questions to please call 1-800-558-8611. And there we have it ; my report . Sonic Regards | ||

| elwoodblue

Senior Member Username: elwoodblue Post Number: 1217 Registered: 6-2002 |

Thanks Wolf, Good info that's not easy to find, Elwood | ||

| lbpesq

Senior Member Username: lbpesq Post Number: 4801 Registered: 7-2004 |

So I guess the moral of the story is "don't use Flitz in Canada"? Hehehehe Bill, tgo | ||

| elwoodblue

Senior Member Username: elwoodblue Post Number: 1219 Registered: 6-2002 |

...or just use Canadian water, ;) | ||

| sonicus

Senior Member Username: sonicus Post Number: 1738 Registered: 5-2009 |

I can just speculate as to what the various parameters seem to be regarding the reasoning regarding how the standards are set from Government to Government as far as stipulations go regarding a product to be legally considered "non-abrasive" . But I would tend to believe that In The U.S. it is a matter of practical functionality rather then pure semantic accuracy. David is correct as far as the chemical composition as per the MSDS. It appears that the legal aspects in definition as far as marketing are not purely based on the chemical composition in the U.S. It would be interesting how much this would vary on a global level. I still think that the Flitz paste in the tube is awesome, But should only be used as directed as per the link in my post #1734 It was VERY effective to polish the silver Alembic Logo on my head stock , as well as the bridge and brass posistion markers and did not damage the finish and cleaned up well ( use only very little and very carefully on a cotton swab). I would not use it if the brass is coated however . As far as Polishing a bridge I tend to remove it from the instrument but Rusty's Bib is a a nice variation if you don't want to remove it . Sonic Regards , Wolf | ||

| cozmik_cowboy

Senior Member Username: cozmik_cowboy Post Number: 911 Registered: 10-2006 |

"...In The U.S. it is a matter of practical functionality rather then pure semantic accuracy." Sort of like US food labeling, where "Fresh, never frozen" means "never frozen below 0° F"? I think marketing might play more of a role than functionality. Peter | ||

| rustyg61

Member Username: rustyg61 Post Number: 55 Registered: 2-2011 |

Thanks Wolf! | ||

| georgie_boy

Senior Member Username: georgie_boy Post Number: 1004 Registered: 8-2005 |

Is all this "Never Dull" stuff just the same as a product we have here in the U K called "Duraglit" ?? There is also one just for Silver type metals. Works great and lasts for ages!! George | ||

| rustyg61

Member Username: rustyg61 Post Number: 62 Registered: 2-2011 |

George, it looks like a very similar product. I'm not sure if it has the same chemicals in it, but definitely the same wadding type polish that works well on brass. |