| Author | Message | ||

| davehouck

Senior Member Username: davehouck Post Number: 972 Registered: 5-2002 |

The latches on one of my racks are loose; and I have acquired replacement latches from SKB. The new latches include the appropriate size rivets. I also happen to have a rivet tool that I have never used; it looks like this: http://www.arrowfastener.com/FMPro?-db=web.fp5&-format=product.html&-lay=Entry&-Op=Equals&item=RL100S&-find= I have no idea how to load or use this tool; I've never riveted anything before. I've searched the web for instructions, but have come up empty. I'm also unsure about removing the old latches. I was told that the best thing to do is to drill out the old rivets; but I've read that when drilling out old rivets, you run the risk of widening the holes and making them unusable for the new rivets. Can anyone provide some guidance to a rivet tool novice? | ||

| son_of_magni

Intermediate Member Username: son_of_magni Post Number: 134 Registered: 1-2004 |

Genericly refered to as "pop" rivets, you select a rivet with the correct diameter, put the pointy end into the tool and poke the big end through the pieces to be riveted. Squeeze everything together and pump the handle. The side with the more finished appearance is the side that the tool is on, so you want to poke it in from the outside. When you drill out the old rivets do it from the outside and don't run the drill through the hole. The drill will seperate the two parts of the rivet before you actually touch anything important, usually you will see the outside part of the rivet start to spin with the drill bit. Then you can just poke the inner part through with a nail and it falls apart. (Message edited by son_of_magni on November 06, 2004) | ||

| davehouck

Senior Member Username: davehouck Post Number: 978 Registered: 5-2002 |

Thanks Karl! I'll give it a try! | ||

| davehouck

Senior Member Username: davehouck Post Number: 979 Registered: 5-2002 |

No matter how long I stare at it, I cannot seem to grasp how it works. I stick the pointy end of the rivet into the hole in the bottom of the tool, and I stick the barrel end through the holes in the pieces to be riveted. Then when you say "pump" the handle, do you mean to pull back on the handle and then sqeeze it down one time? What happens once you do this? How does the tool make the rivet flare out on the far end and snugly hold everything together? | ||

| poor_nigel

Advanced Member Username: poor_nigel Post Number: 362 Registered: 7-2003 |

The rivet(s) you are using is like a ball headed nail in a tube (Barrel). When you start squeezing the handle, the nail is pulled into the tool, the ball end is pulled into the tube, widening the tube as it is drawn deeper. You keep pumping the handle until it pulls so hard that the nail end breaks off, leaving the ball end in the barrel, making the barrel snugged into the hole, which is now holding the two piece together it was slipped through. | ||

| davehouck

Senior Member Username: davehouck Post Number: 981 Registered: 5-2002 |

Thanks Nigel! The explanation makes sense, though it's still hard to see it looking at the rivet itself. I'll give it a try later today or tomorrow. | ||

| bsee

Senior Member Username: bsee Post Number: 437 Registered: 3-2004 |

Rivets are cheap - just drill a hole in some scrap material of similar thickness and try one where it doesn't matter. You also might want to do this to make sure you have the right size rivets for the project you're working on. You probably need a fairly long rivet to go through the plywood of a case. | ||

| davehouck

Senior Member Username: davehouck Post Number: 983 Registered: 5-2002 |

Bob, that's a good idea. The case is an SKB; no plywood, so it's relatively thin. | ||

| son_of_magni

Intermediate Member Username: son_of_magni Post Number: 135 Registered: 1-2004 |

It usually takes three or four cranks of the handle before the nail "pop"s off. Then release the handle to let the nail fall out of the tool, but don't leave the nails in your driveway like I did when I riveted some sheet metal on my car... | ||

| shellfish

New Username: shellfish Post Number: 9 Registered: 9-2004 |

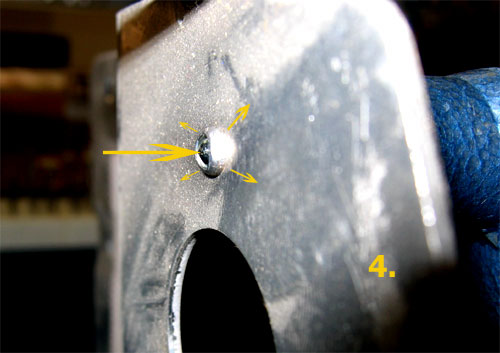

Some pics?      This rivet tool cuts nail at proper moment (damn pragmatic these germans... ;) )   It's that easy! Kai | ||

| poor_nigel

Advanced Member Username: poor_nigel Post Number: 364 Registered: 7-2003 |

Hey Kai. What a great post! | ||

| davehouck

Senior Member Username: davehouck Post Number: 986 Registered: 5-2002 |

Great pics! Thanks! And I see that the instruction is to pull back on the handle before inserting the rivet; that makes sense. | ||

| davehouck

Senior Member Username: davehouck Post Number: 1008 Registered: 5-2002 |

Success!! Thanks guys; my rack has new latches! | ||

| hollis

Senior Member Username: hollis Post Number: 509 Registered: 11-2003 |

Man, I love this club. Great post Kai! |