| Author | Message | ||

| jlpicard

Advanced Member Username: jlpicard Post Number: 324 Registered: 7-2002 |

Can anyone fill me in on the details of Alembic's finishing process beyond what is on their website? I'd like to know more about the fine details of finishing with polyester. I like to build/and or modify a bass from time to time and I've only attempted oil and poly/oil coating mostly due to lack of tools and space. Here's an original 70's Charvel P-bass that I modded in '92 that kind of reminds me of an Excel.  It has the oil/poly combo that I spoke of. | ||

| jlpicard

Advanced Member Username: jlpicard Post Number: 325 Registered: 7-2002 |

Here's a few more;   (Message edited by davehouck on January 23, 2006) | ||

| bigredbass

Senior Member Username: bigredbass Post Number: 590 Registered: 9-2002 |

The part I remember is that they use NO fillers/sanding sealers to level the grain out of the wood the easy way. The wood wouldn't be as remarkable looking if they did. And considering the woods involved that's saying a lot. Everybody's favorite cocobolo is actually toxic to humans. Ever try sanding ebony? Much less the wood Mica was saying smells like a wet dog while you're working it . . . Once it's prepped to shoot, they shoot/dry/wet-sand as many times as it takes until the finish is glass flat. Let's say 15 or 20 times, maybe more. Any wonder they take that long to finish a build? J o e y | ||

| lbpesq

Senior Member Username: lbpesq Post Number: 902 Registered: 7-2004 |

Wouldn't it actually smell like a wet Zebra? LOL Bill, tgo | ||

| precarius

Junior Username: precarius Post Number: 36 Registered: 11-2005 |

I know cocobolo is toxic the hard way. I made a jewelry box for my daughter with cocobolo and while I was sanding it, I breathed some of the dust in through my nose and I ended up with an hour-long nosebleed. No dustmask of course. I R stoopid. | ||

| trekster

Member Username: trekster Post Number: 64 Registered: 7-2004 |

My reaction was worse.. it was a warm day when I was sanding some cocobolo and I was sweating pretty good...everywhere I was really dripping (mostly under my breasts -- at the time I was 365 lbs), I broke out in white-pus, painful rash zits. NEVER AGAIN. --T | ||

| bassman10096

Senior Member Username: bassman10096 Post Number: 838 Registered: 7-2003 |

Yup. Coco bolo is ugly to work with. And I've never reacted remotely as badly as you guys. But...a great headache from the dust (even with a mask) - sure! I'm finishing a CB bass body right now. It was not my understanding that Alembic avoided sealers when they finish CB - just no grain filler (which would really look bad on the orange wonder-wood). I put on 6 coats of sand and seal and approximately 10 of lacquer and the finish is still drying into the pores a little bit. Sure is pretty, though. Unlike anything else I've seen or painted. | ||

| bassman10096

Senior Member Username: bassman10096 Post Number: 839 Registered: 7-2003 |

Michael: For polyester finishing, you'd need a full spray outfit. On the other hand, nitro comes in rattle cans, produces a good shiny finish but is somewhat less durable than polyester or urethane. I've gotten really good results with nitro. I've finished a few guitars with spray urethane, too. Harder to work with (thin and runs easily) and horribly hard to sand once it runs. You also need to watch the wood you attempt with any poly finish - oily woods (e.g. coco bolo, some rosewoods, ebony and others) won't let the finish dry unless you can custom mix the lacquer (way beyond my scope at this point!). Nitro dries on almost anything. Nice looking bass. | ||

| mica

Moderator Username: mica Post Number: 3011 Registered: 6-2000 |

We only fill the grain with paint (that's the clear stuff!), or coating if you prefer the industrial term. You spray a layer, sand and prep for the next. If the grain is very deep, or full of wells like burl, you sand most of the paint off until the little wells fill up. Once they are full, you can sand more lightly for the prep. Do watch for runs as Bill said! Better to spray more thin coats than to fight globby runs. Clean oily woods with acetone just before spraying to get those pesky oils out of the way. You'll have to test to see if your paint sticks to the oily woods. You can always sand it off. You might want to practice on just some boards as you perfect your srpaying technique and test the paint on various woods. However, if you've already got an oil finish on the bass, I'd probably stick with it. The oil penetrates the wood and may make any painting difficult. | ||

| bassman10096

Senior Member Username: bassman10096 Post Number: 840 Registered: 7-2003 |

Wow, Mica. That's a lot of clear coat to fill all the gaps and grain. You know - even with an acetone rub, I've been unable to get anything except nitro to dry on coco bolo. Fortunately, despite a few durability issues, a super-well-polished (micromesh to 12,000 grit), well-cured nitro finish makes CB look just like jewelry. Also Michael - I forgot to add: With ANY spray finishes, buy a respirator at the hardware store ($20 and up) and WEAR IT RELIGIOUSLY! Your brain cells will thank you a lot. I know a lot of people who have had very bad reactions to inhaling those fumes - especially nitrocellulose. Other safety issues - have adequate ventilation so your family, pets, etc are not treated to an overdose of fumes. Watch for sparks and flames, including not spraying in your furnace room without turning off the pilot or the furnace itself - until the fumes clear out. If you use an exhaust fan, a non-sparking starter is much safer. Bill (Message edited by bassman10096 on January 24, 2006) | ||

| jlpicard

Advanced Member Username: jlpicard Post Number: 327 Registered: 7-2002 |

I always wear a respirator even while I'm sanding. After a few minutes without one my nose starts running. Allergies, I hate them! Oddly enough I have done some sanding of cocobolo in the past unprotected and not experienced any noticable affects other than the aforementioned nose discomfort. Just lucky I guess. Thanks for the advice. It sounds like a big job, something i'm not quite ready to tackle. There are some new water based finishes that come highly recommended from LMI (Luthiers Merchantile Inc.)that are actually brushable, self leveling and compare favorably to nitro for looks so I may go that route for now By the way, I don't plan on changing the finish on this bass. I like the look of the oil /poly finish as it is . My interest is for a future project, one that I started many years ago,(81') I believe. It has sat around in pieces all this time and I have finally decided to finish it. They say imitation is the sincerest form of flattery. I hope you'll agree. ;)   Please bare in mind that I did not have a bass available from which to make a template for the body. There were precious few pictures of Series basses around at the time especially one that was a direct frontal camera angle that I could use to get the body contours right. I finally found a photo of three series basses standing together on one page. A graphite neck short scale in koa, a bubinga large standard with point body and a series II in walnut with an Omega cut. The literature states that Alembic was located at 45 Foley street at the time of this photo. The headstock, I tried my best to copy from John Judge's 's bass in the now famous Superwound string ad. Anyway, for sentimental reasons,I hope to finish someday. Hopefully,that wood should be pretty darn stable by now? | ||

| bracheen

Senior Member Username: bracheen Post Number: 969 Registered: 11-2003 |

I don't care how it smells that is a beautiful piece of wood! The stripes look great running vertically. Sam | ||

| bassman10096

Senior Member Username: bassman10096 Post Number: 841 Registered: 7-2003 |

Great wood. That bass definitely deserves to be finished and shown to the world. Nice work. Getting back to finishes, if you do try the water-based stuff, let us know how you like the results. Seems like there is quite a stir about it, but I haven't seen a water-based finish or talked to anyone with hands on experience. BTW - Sorry for the heavy-handed safety advice. Sounds like you've got matters well in hand. I'd just hate to take the chance that someone else reading here might try a hazardous finishing process without knowing how to stay safe. Bill | ||

| jazzyvee

Advanced Member Username: jazzyvee Post Number: 333 Registered: 6-2002 |

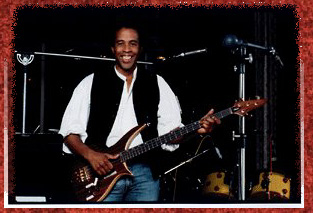

I knew that first bass picture reminded me of another bass I'd seen Clarkee with. Here is the photo.  The bass clarkee has looks a real nice shape. Is it an alembic if not what is it? Is it another one of those rare project basses like the elusive spellbinders? Jazzyvee | ||

| jlpicard

Advanced Member Username: jlpicard Post Number: 328 Registered: 7-2002 |

Sam, did you mean to say the grain is running horizontaly on the Zebrawood bass? Actually the grain is running normally ,verticaly or top to bottom as is normal. I just happened to luck out. Macbeath hardwood let me go through their Zebrawood pile and I found this really cool piece of curved grain. Bookmatched it and positioned it just right to fit a large standard body shape and there you have it. | ||

| 811952

Senior Member Username: 811952 Post Number: 635 Registered: 10-2003 |

It's a Tune bass, isn't it?? | ||

| bracheen

Senior Member Username: bracheen Post Number: 970 Registered: 11-2003 |

Yes that's what I meant. Perpendicular to the neck whether that's horizontal or vertical. Most Zebrawood I've seen is oriented the other way which still looks good. I just like Zebrawood however the grain runs. Sam (Message edited by bracheen on January 25, 2006) |